Plastic Injection Molding

Injection Molding Services

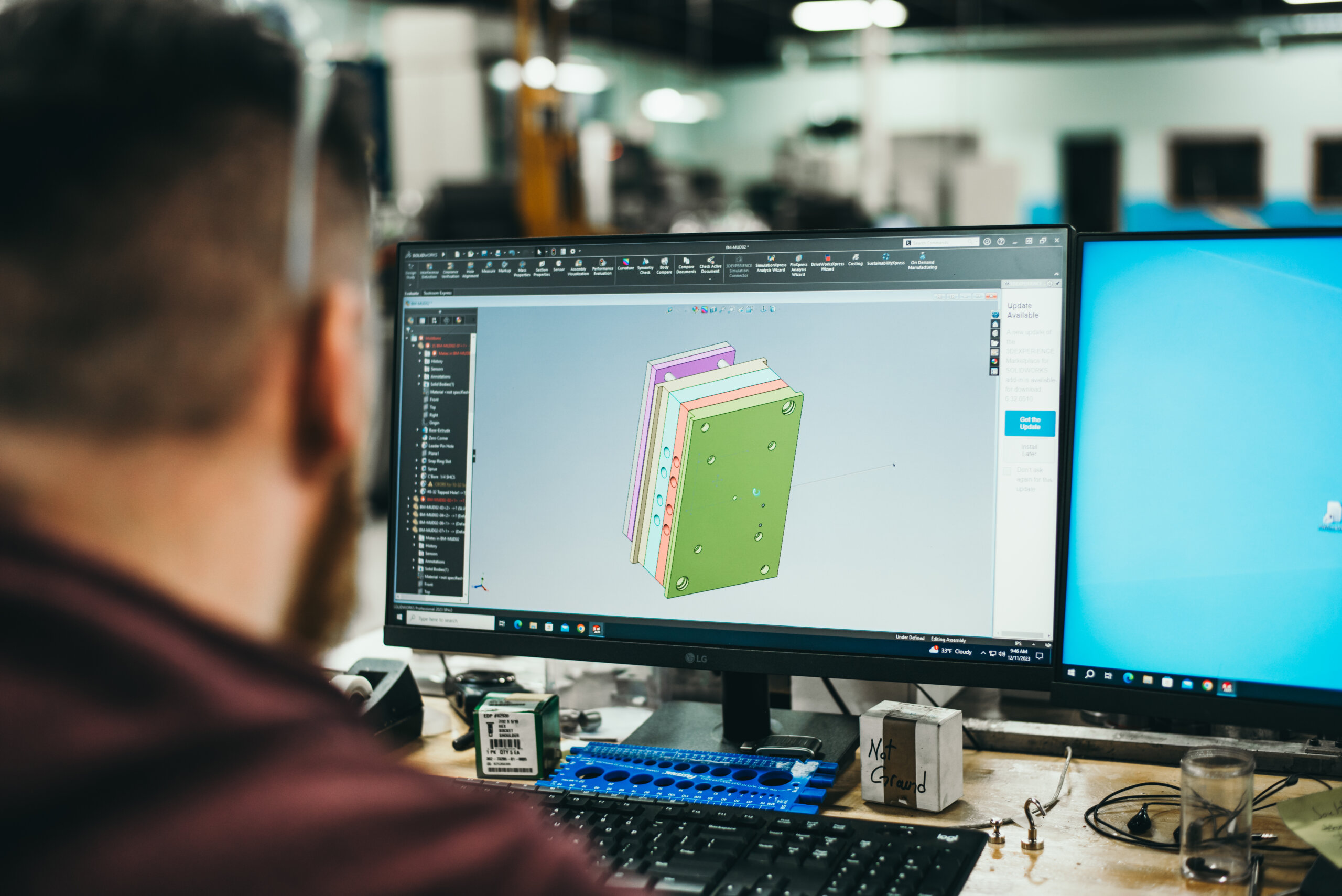

At Four Square, we do much more than make parts. We solve complex problems with custom engineered solutions.

Our team handles every stage of the product development life cycle – from part design, engineering, and mold design to construction, injection molding, and secondary services.

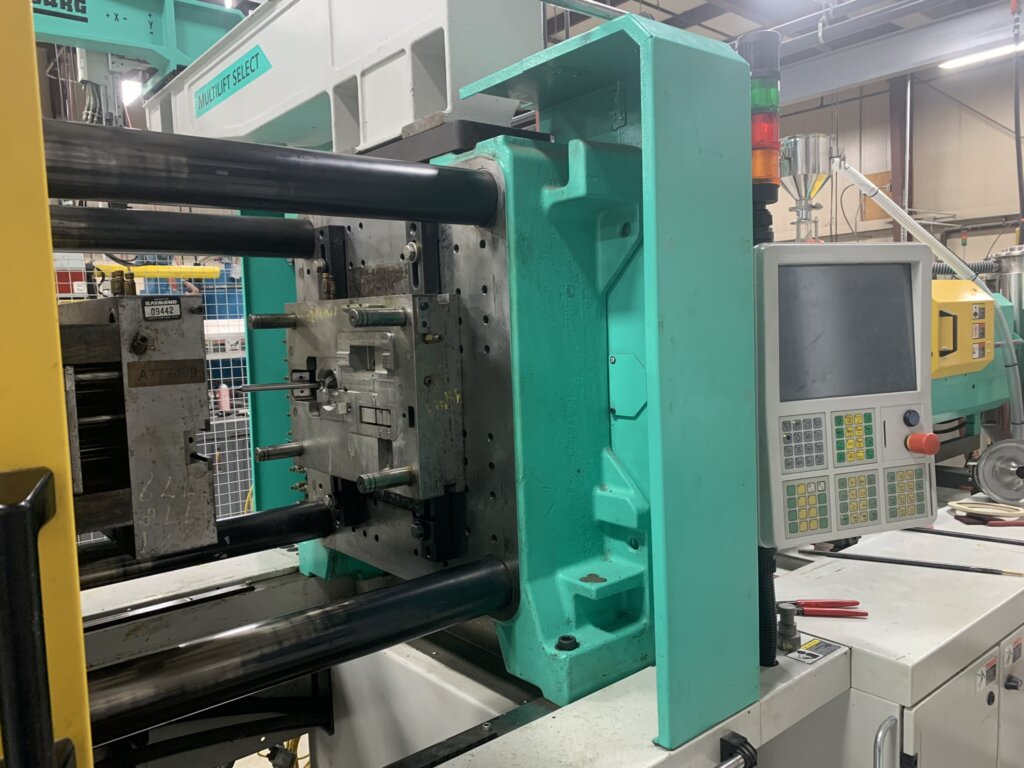

Injection Molding Process

After the initial design and engineering phase, your part goes into production at our full-service facility. We have a range of machine sizes from 28 tons up through 730 tons. This wide range allows us to run your mold in the optimum machine size. We specialize in insert and over-molding with numerous dedicated machines. We have extensive experience in a wide range of engineered molding resins. Our vast experience, along with our wide range of machines and capabilities allows us to deliver to you the part as designed.

Once the parts are molded we offer a complete list of secondary services to finish your part to your specifications.

Features

- Overmolding

- Insert Molding

- Internal/External Threads

- No Quantity Requirements

- Undercuts

- Multi-Component Family Molds

- Complex design features

- Thin wall features

- Tight Tolerances